Surface Treatments

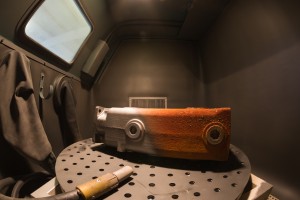

Micro Blasting

Micro Blasting

Parts can be cleaned, have old coating removed, surfaces treated (rough or smooth), by blasting techniques using various media. Many different types of material including aluminum oxides, plastics and glass beads can be used to attain the desired surface texture.

Vapor Degreasing

A part is suspended above a bath where heated cleaning solutions pass vapor over the part to clean away any surface contaminants such as grease and oils.

Cold Gas Plasma

This process consists of a radio frequency excitation of gaseous products at very low pressure. The temperature of the gas in the vacuum chamber is essentially ambient, so the parts do not heat up. Cold Gas Plasma can alter the physical and /or chemical reactivity of the surface, while bulk properties remain unaffected. Examples of use are cleaning, etching, and increasing bondability. By using Cold Gas Plasma, we are able to improve a coating’s adhesion to most substrates. It does not affect the substrate material; it does not leave a residue; and it is workplace and environmentally clean and safe.

Uses of Gas Plasma Treatment

- Cleaning Substrate

- Change the Wetting Characteristics: Hydrophobic or Hydrophilic

- Surface Etching

- Plasma Induced Grafting

- Polymer Deposition

- Sterilization

Ultrasonic Cleaning

Parts are immersed in a liquid bath and then agitated by ultrasonic means to remove any contaminants.

Other Surface Treatment Options

We currently work with Summit Plating, a Connecticut company, to accommodate customers who would like to add electro-plating to their parts.

We also currently work with The Lake Grinding, a Connecticut company, for parts that would benefit from the addition of centerless grinding.

For more information regarding surface treatment, please contact us.